Solar Irradiation Simulator

To Test IEC 62217

High quality custom solution from design to delivery, leveraging existing expertise.

Electrical Research and Development Association (ERDA)

Electrical Research and Development Association popularly known, as "ERDA" us a premier Testing Calibration, Certification and research organization of India. ERDA (www.erda.org) was established by the Indian Electrical Industries & Utilities with the support of the government of India and Gujarat and has acquired four decades of experience as a service provider. It is a not-for-profit sector organization.

Ideation and Design for The Solar Irradiation Simulator

Requirements

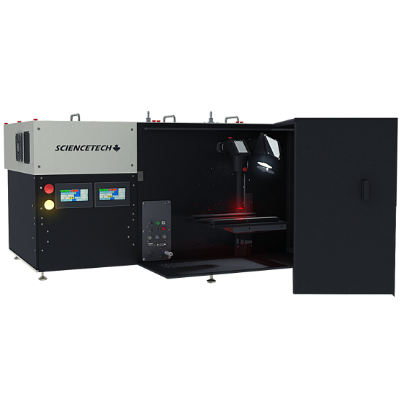

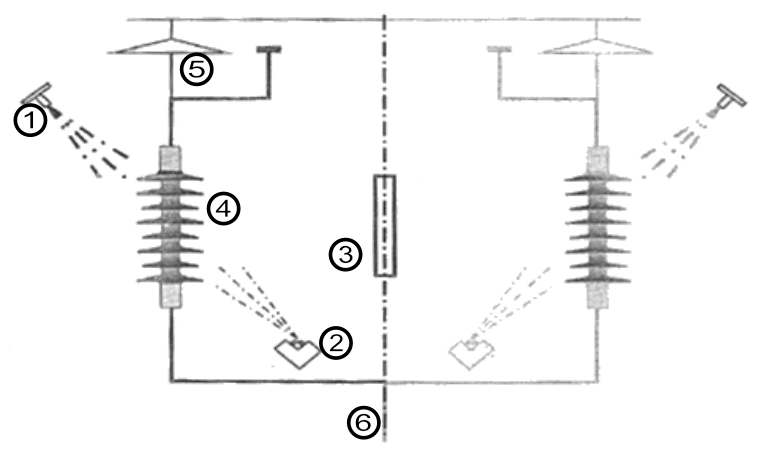

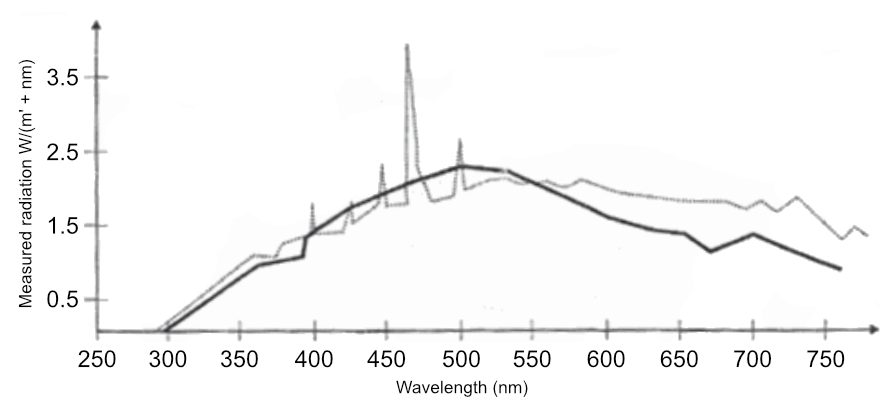

Following IEC: 62217 B.3.2 of stress testing high voltage insulators Sciencetech was sourced to design a solar simulator for irradiation provided by a xenon arc lamp with a nominal output of 6500w and equipped with boron silicate glass filters. The distance between the xenon lamp and test specimens is approximately 480mm.

Challenge

This Solar simulator had to withstand harsh environments of

continuous testing with artificial rain containing salt as well as a

temperature cycling from low temperatures up to 50c in 15 minutes.

Key:

Reliability

The Solar simulator had to cycle the stress test of the high voltages insulators for a period of 5000 hours with minimal interruptions for maintenance.

Requirements to Design the Solar Irradiation Simulator

End User Interaction

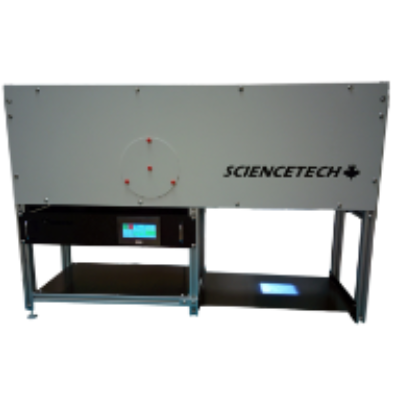

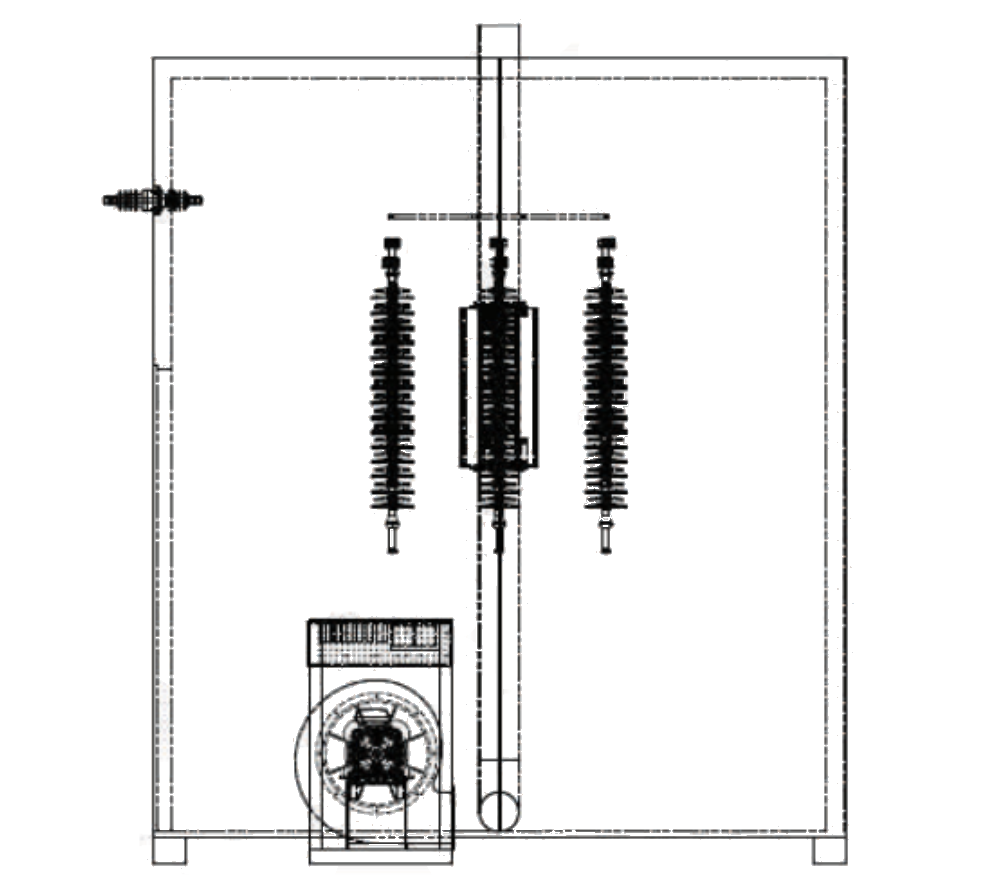

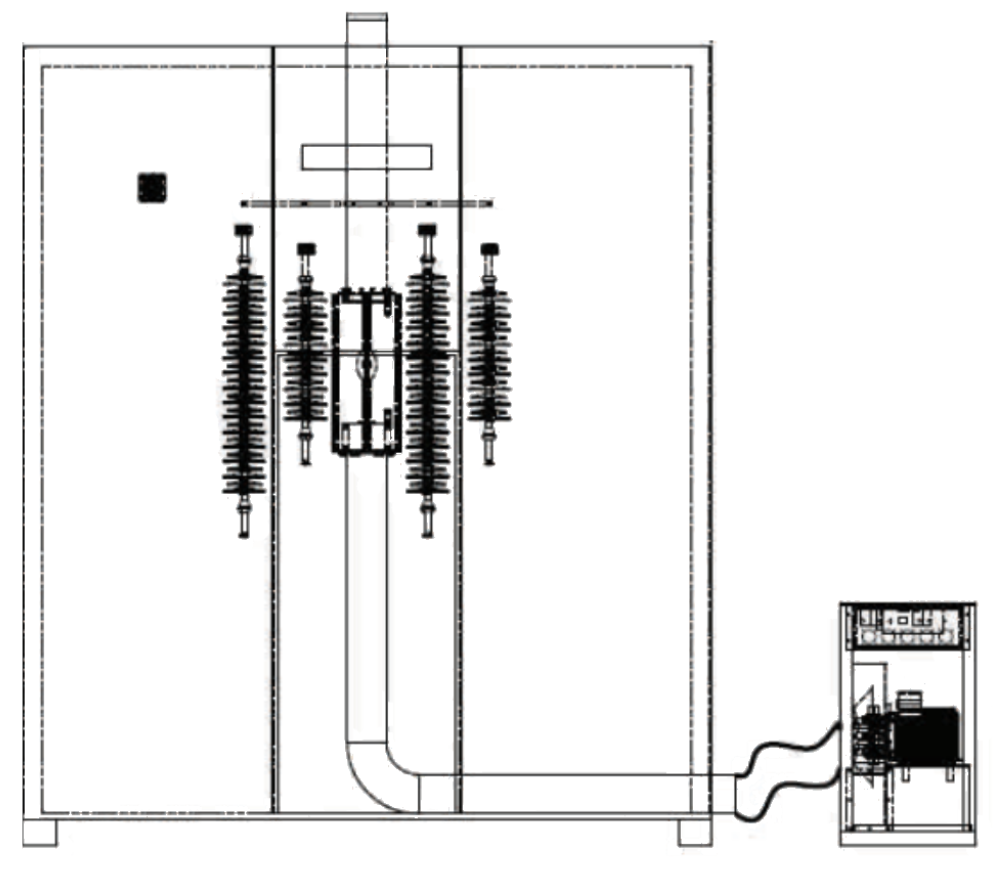

During the design phase of this solar simulator, Sciencetech collaborated with ERDA for all the relevant and required information to design the new 6500w solar simulator to fit into their existing climatic chamber.

Collaboration

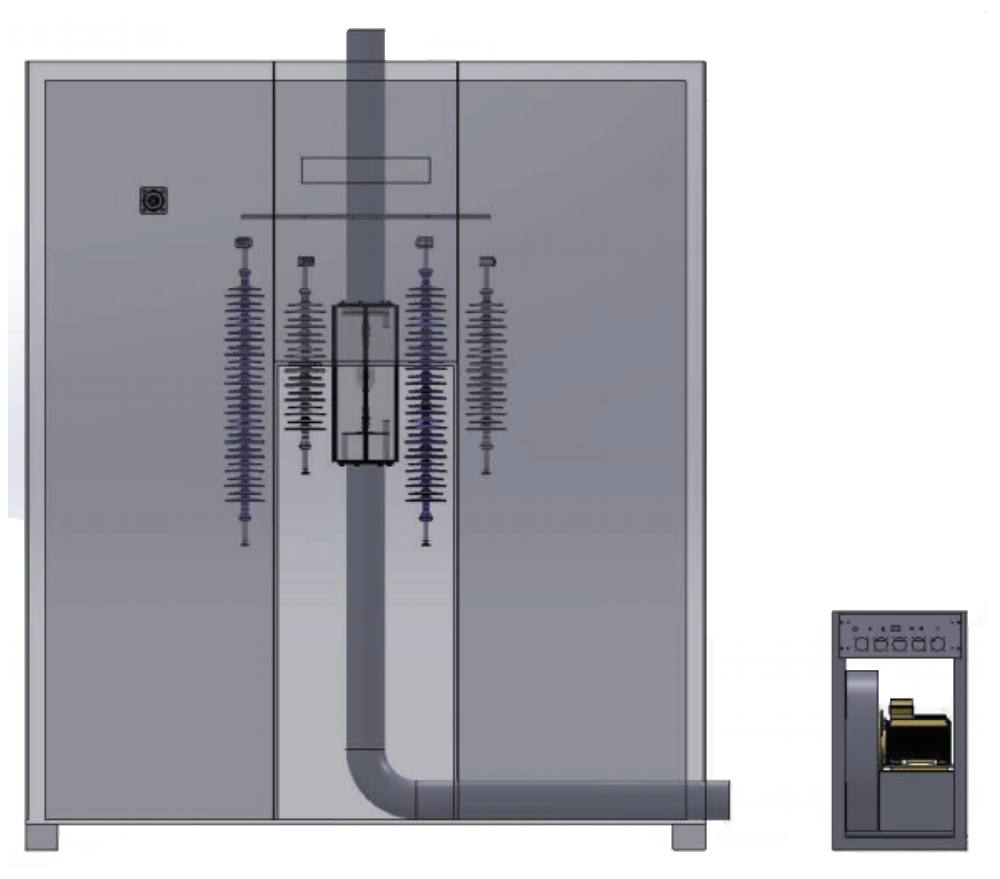

Sciencetech utilizes the most recent CAD software allowing us to interact with ERDA’s engineer’s with 3D models to ensure we find the perfect solution for the modification of the existing climatic chamber to be retrofitted with Sciencetech final solar simulator solution.

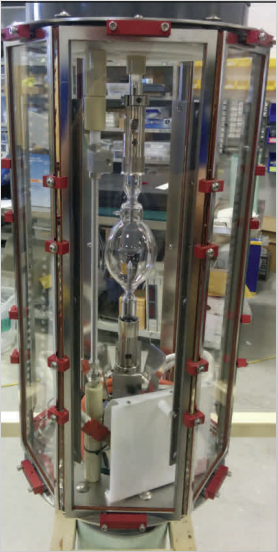

Fabricating the Solar Irradiation Simulator

Mechanical

Sciencetech utilized it’s in house machine shop and assembly area that specialize in all materials to fabricate a fully stainless steel electro polished lamp housing that will protect the 6500w xenon arc lamp from the harsh environment during the 6000 hours of testing.

Electrical

Sciencetech utilized its 6500w xenon arc lamp power supply for this solar simulator with some customization. This project included a PLC for automation and cycle testing of the High voltage insulators. As well as safety interlocks for user protection.