Custom Large Area IR Solar Simulator

This custom solar simulator provides illumination in the infrared wavelengths with high spatial uniformity and depth of field

Client Needs

Sciencetech custom-built this solar simulator for an internationally recognized consumer electronics manufacturer. This solar simulator will be used in their research and development center for testing electronic hardware and semiconductors.

This system emits infrared wavelengths in the region of 700 - 1100 nm and illuminates target areas of 1.0 m² and 1.5 m² at 1 sun intensity. Below is a table summarizing our client’s requirements:

| Requirement | Description |

| Target Area | Illuminates a 1.5 m² area |

| Spectrum |

Class A (ASTM E27)

Wavelength range: 700 - 1100 nm |

| Intensity |

Equivalent to 1 sun irradiance

in the range of 700 - 1100 nm |

| Uniformity |

1 m² : ± 10% (ASTM E927)

1.5 m² : ± 30% (ASTM E927) |

| Depth of Field |

± 15 cm, with change

≤ ± 5% intensity (ASTM E927) |

| Attenuation | 10 steps, 0.1 suns to 1.0 suns |

| T. Instability | Class A (ASTM E927) |

| Warm Up | ≤ 15 seconds |

Complex Technical Requirements

Ideation and System Design

When the optical axis of a light source is perpendicular to a target plane, there is symmetry at all edges of the target plane. This property is used in the design of all standard solar simulators to generate a spatially uniform light field.

Standard solar simulators produce a spatially uniform target plane that is perpendicular to the optical axis of the light source. When the optical axis of a light source is perpendicular to a target plane, there is symmetry at all edges of the target plane. It is simpler to achieve spatial uniformity when this symmetry can be used. Due to the customer requirements, the solar simulator was required to be placed approximately 30° off the optical axis of the target plane. Therefore, spatial uniformity needed to be achieved through research and development of a new optical homogenization system.

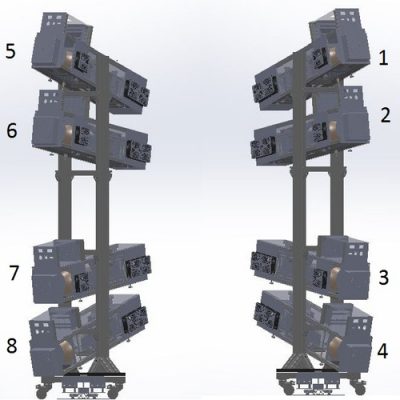

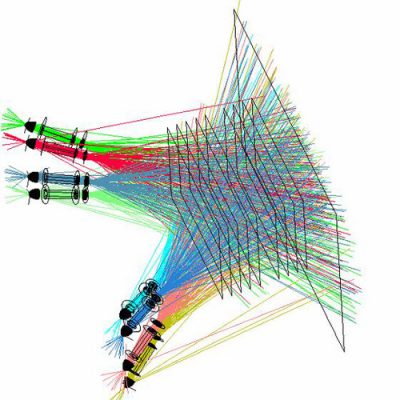

A simulated model of the projector units envisioned to be manufactured

Optical ray tracing model

I) Optical Modeling

Sciencetech engineering team used extensive optical modeling to simulate a single projector and homogenizing system that could achieve spatially uniform light over the required volume. Later, a solar simulator containing several projector systems were arrayed and the positions of the projectors were optimized using optical modeling software to achieve a uniform volume of light.

A special software was made to model the resultant spectral profile when different optical materials and sources were combined. A number of filters and sources were selected and evaluated to determine if an ideal combination of a light source, optics such as lenses and mirrors as well as filters could be found. Special attention was given to the budget of the project when selecting the ideal optical combination. Quartz tungsten halogen (QTH) lamps were determined to be the best light source to simulate the light, considering its smooth IR emission.

Testing of a single projector was performed to evaluate uniformity and stability

A simulated optical grid for measuring the uniformity in a three dimensional space was developed for further testing purposes.

II) Durability Testing

Temperature resistance testing was performed to determine if the selected optical materials and filters could survive the high optical power output of the lamps. The testing was also performed to determine the required air flow rate and type and positioning of fans to be used for the cooling purposes of the system.

III) Irradiance Attenuation

Optical modeling was conducted to determine the best size and location for an attenuator that would meet the project’s attenuation requirements.

Prototype Design Implementation

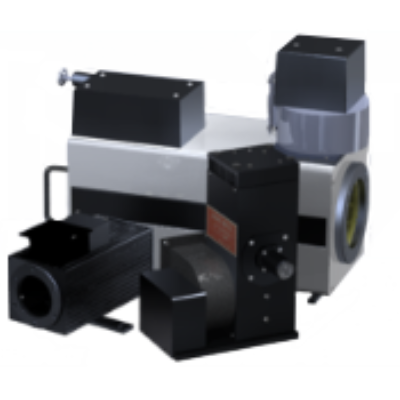

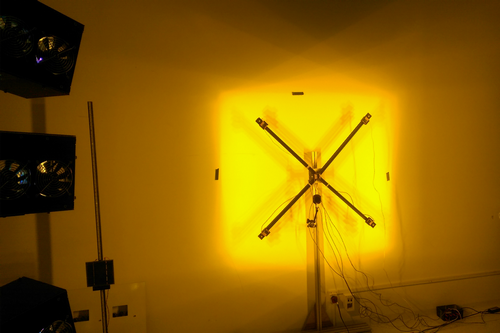

Eight projector units were used for the design and illumination of the required target area. Each optical projector unit consisted of a 2 kW QTH lamp with a quartz envelope held within an elliptical reflector. Each unit also contained a homogenizing assembly to achieve the required uniformity requirements. The spatial uniformity specifications were successfully achieved after meticulously designing and fine-tuning the system.

Furthermore, field lenses and projection lenses as well as long-pass filters to remove unwanted wavelength ranges were integrated into the QTH lamp systems.

The optical power was sufficient to achieve the required power levels in the 700-1100nm region over the full, three dimensional volume. The system provided the required irradiance (ASTM E927) at the target plane when measured for 700nm - 1100 nm spectral outputs. The shape of the spectral output matched the ASTM AM1.5G curve for 700 - 1100 nm wavelengths. The working distance was also set to be adjustable to accommodate the two different focal lengths.

An inexpensive optical system was designed and produced to achieve the promised spatial uniformity, spectrum and optical power. The optics and filter were sufficiently cooled using fans. The system was capable of attenuating the output irradiance in incremental steps of 10% while maintaining the spatial uniformity of the output light.

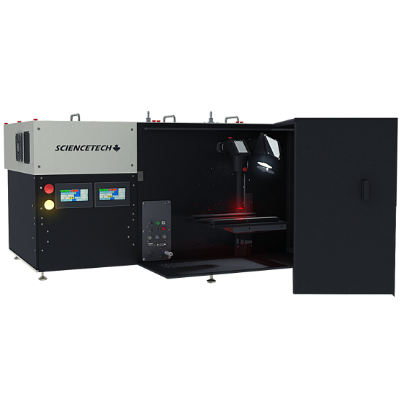

Testing and Installation

The system was successfully completed and installation and training was conducted by Sciencetech Engineers at the location of the customer’s laboratory.

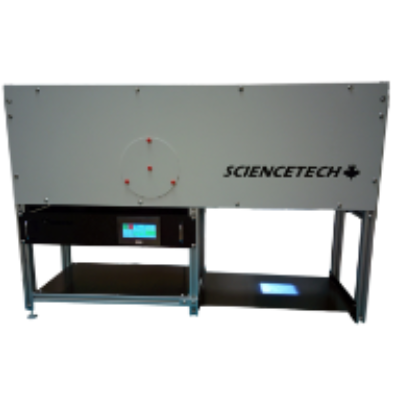

Pictured is the final solar simulator system illuminating a 1.5 m² target area.