Highly Collimated Fresnel Solar Simulator

For Space Environment Simulation

This solar simulator was designed to produce highly collimated light and was developed to operate inside a vacuum chamber.

Customer Requirements

A researcher from a renowned space agency approached Sciencetech to custom-design a high-powered, collimated solar simulator capable of being placed within a vacuum chamber. The solar simulator was to be a part of a larger system designed to simulate extra-terrestrial environments in a controlled laboratory.

Customer requirements:

Optical Design and Implementation

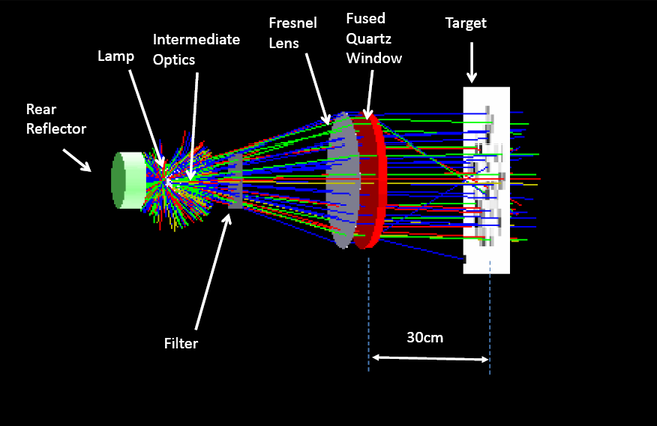

Numerous ray tracing models were developed to assess the optical characteristics of the proposed solar simulator design. After several iterations, a suitable optical design was proposed to achieve the required specifications.

Optical ray path simulation to obtain high collimation for the output of the solar simulator

Achieving the Collimation Angle

At the heart of the system, a 2.5 kW xenon arc lamp was used to collect the light with a lamp house containing a spherical back reflector. The collimation angle was achieved with an intricate optical assembly that contained a Fresnel lens system.

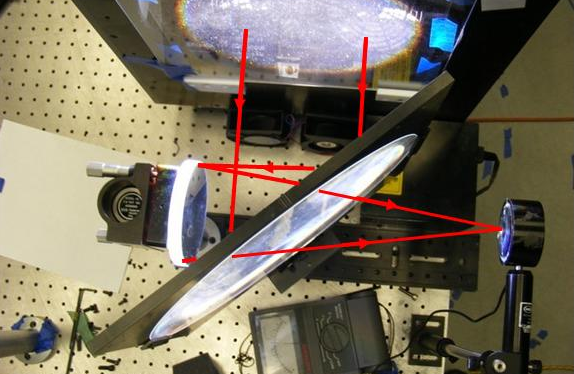

The collimation angle of the simulated light rays was determined by measuring the amount of optical power passed through apertures of varying sizes placed at the focal plane of a mirror.

The tests were conducted when the light emerging from the solar simulator was reflected at 45° off of a very thin quartz plate ( with 4% surface reflection). Light reflected from the quartz plate was retro-reflected by an aluminum coated spherical mirror with a known focal length. Apertures with sizes from 1.5 mm to 15 mm were placed at the focal plane of the spherical mirror and the optical power emerging through the apertures were measured with a NIST traceable silicon detector.

Testing conducted with the use of Fresnel lens system to achieve the required high collimation

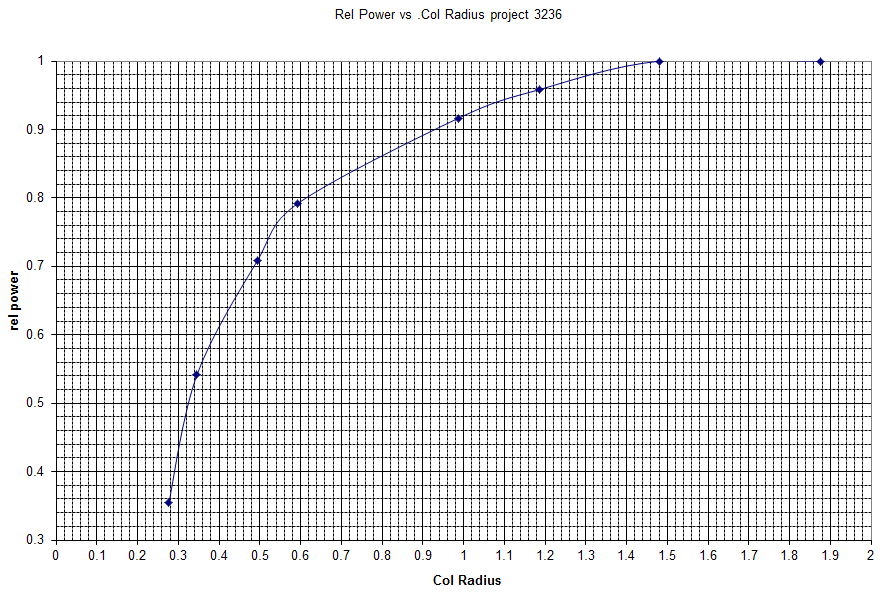

Collimation measurements of the system which show > 80% of the optical power within ± 0.7°

An acceptable collimation is defined as > 50% of the optical power falling within a collimation radius of 0.7 degrees. With this optical design, we were able to obtain more than 80% of the optical power within ±0.7 degrees of the collimation angle.

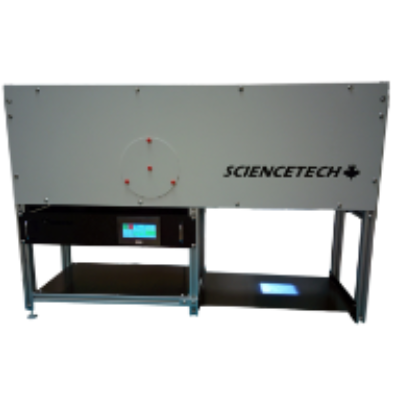

Achieving Vacuum Compatibility

The solar simulator was required to be leak-proof in order to be hosted within a vacuum chamber. Vacuum-compatible solar simulator housing was designed by Sciencetech engineers. Housing feedthroughs for coolant and electrical components were specially sourced in order to be vacuum compatible. The walls and housing of the solar simulator were made of SAE 304 stainless steel with an electropolish finish. The solar simulator housing was specifically manufactured by a professional vacuum system engineering company and was guaranteed to be leak-tight as tested with a mass spectrometer leak detector possessing calibrated minimum sensitivity of 2x10 -10 cc/sec of helium.

The solar simulator housing being monitored for leaks

A 15” diameter 1” thick Quartz window was used at the front optical output. High quality pressure windows were sourced to manufacture this optical output window.

The solar simulator housing was over pressured to 2 atm and monitored for 12 hours for any potential leaks.

Window dimensions were result of research and calculation. High quality pressure windows were sourced to manufacture the optical output window.

Achieving Temperature Stability

Below are the requirements of the end user for temperature maintenance of the system.

Testing the Temperature Stability

Sciencetech engineers determined that the best approach was to build a pressure vessel to house the simulator and optics. The pressure vessel allowed cold liquid to be pumped into the chamber and routed to a series of radiators which performed heat transferring inside the chamber via forced air through the radiators. The anode and cathode of the lamp base was cooled with a water re-circulator filled with de-ionized water.

Since Sciencetech is committed to providing the best solutions to complex engineering problems, we specifically built a test chamber to perform these cooling experiments. We progressed through a series of failed prototypes and burnt-out lamps and power supplies before arriving at a successful cooling system.

Control electronics were designed specially to be integrated with the solar simulator. Internal system temperature sensors and coolant flow sensors were built in to protect the system in case of any component malfunctioning. Temperature sensors were also placed at two different locations inside the housing to monitor the internal air temperature.

Another temperature sensor was used to monitor the temperature of the water bath in the re-circulator that was used to cool the lamp bases.

A logic circuit was used to turn off the lamp in case an over temperature condition occurs at a lamp base or inside the housing. The logic circuit was used to set temperature points and to control a relay which will cut power to the lamp in case of an over temperature event.

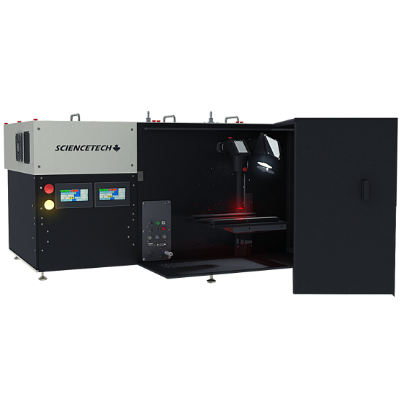

Quality Control and Installation

The final solar simulator system was built and a series of tests were performed to prove capabilities of the housing to maintain required temperatures and vacuum compatibility. All optical design tests were conducted ahead of time to ensure the required optical power, spectral match, collimation angles and other specifications requested by the end-users were met.

The system went through an on-site acceptance testing procedure at the end-user’s facilities and was installed by Sciencetech’s service engineers.