Upper Atmosphere Solar Simulator

For Photochemistry in Air Pollution Studies

This solar simulator produces solar spectrum found in the upper atmosphere

Research scientists contacted Sciencetech to develop a customized solar simulator for a high priority government research program. They had unique and specific spectral requirements for studying air pollution effects and photo-chemistry in the upper atmosphere. The client’s sample chamber was a rotating cylindrical drum holding suspended aerosols and this needed a uniform and collimated illumination. However, the tight laboratory space and the presence of other equipment connected to the sample drum imposed multiple constraints on Sciencetech’s proposed solution.

Customer Requirements

Complex Technical Requirements

Ideation and Designing the System

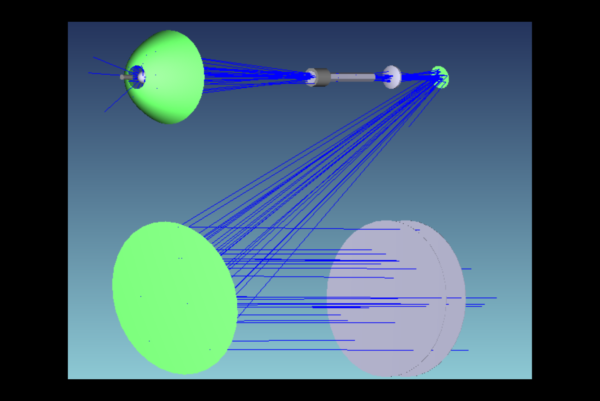

During the initial concept designing phase, a few different ray tracing models were produced to assess the most effective optical design. Finding the correct geometrical positions of the optical elements also required several alterations to the optical designs. Multiple ray tracing simulations were conducted to assess the collimation and irradiance profile.

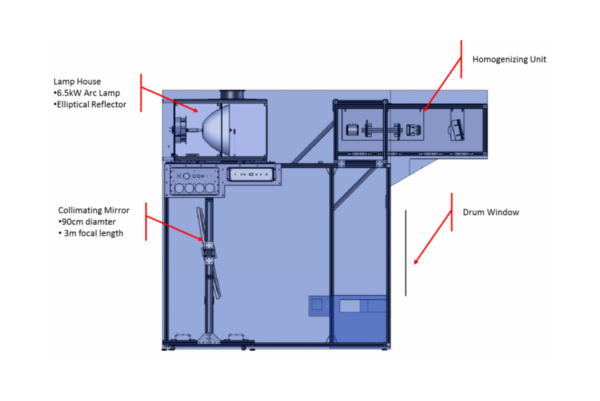

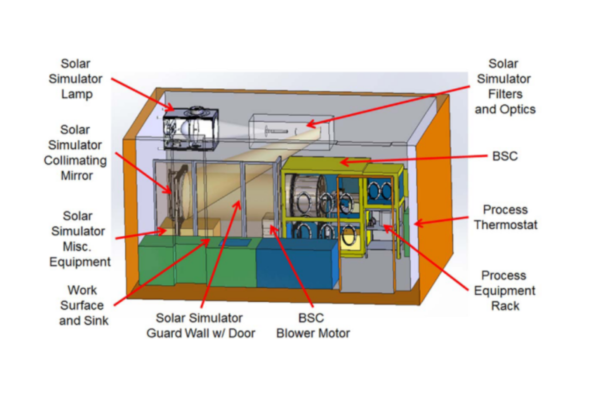

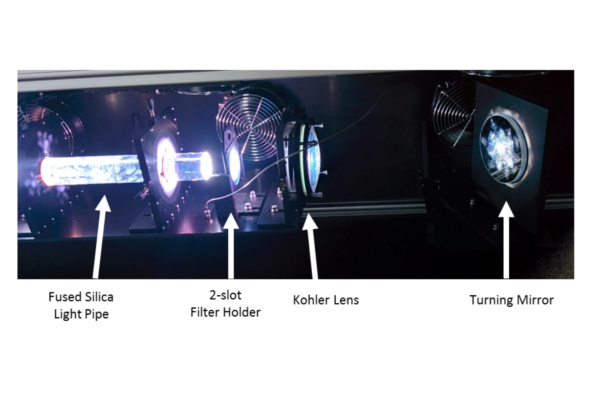

At the heart of the system is a 6500 W xenon short-arc lamp and deep elliptical reflector to produce and redirect the maximal optical power into the homogenization system. A custom specified and highly purified fused silica homogenizing rod was used to achieve the required spatial uniformity in the sample drum. The homogenized light was directed through a Koehler lens configuration, folded back by a turning mirror, and again folded back and directed into the sample drum by the collimating mirror. The almost one meter diameter collimating mirror with a 3 m focal length was specially produced by one of Sciencetech’s lens suppliers and tested by Sciencetech to confirm that the target irradiance profile was achieved.

.png)

Spectral Filters

A special spectral filter was custom designed to simulate the solar spectrum according to the client’s requirements. Several hundred Watts of unwanted infrared wavelengths were absorbed by water in Sciencetech’s liquid filter and the heat energy was dissipated using a recirculating cooling system.

Optical component layout of the solar simulator system

Ray tracing path model performed for the optical design of the solar simulator

During the design evaluation stage of the project, the Sciencetech engineering team performed a bench test to compare the theoretical calculations with the actual light source efficiency.

Extensive calculations were performed to model the resultant spectral profile of the solar simulator with the optical power expected at the target plane. The bench test also helped in selecting the appropriate coatings and materials required for the optical setup such as the lenses, mirrors and homogenizing light pipe.

The materials used in this project required to be able to endure high optical power densities with a significant emission of UV. Therefore, determining the durability and performance of the materials being used was an important aspect of the evaluation of the project.

A comprehensive 3D drawing of the internal components of the system and conceptual optical path

A photo taken of the light traveling through the homogenizing optical assembly

Testing and Installation

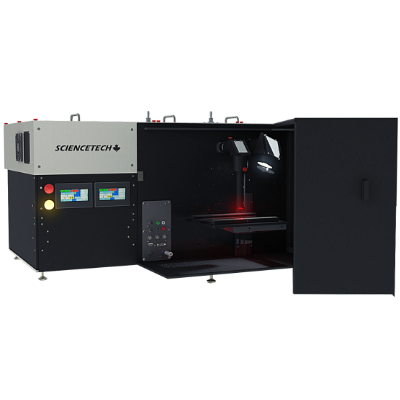

During the production stage of the solar simulator system, a special 3-axis motorized measurement stage was developed in order to measure the irradiance profile and spatial uniformity throughout the target volume.

Sciencetech’s calibrated spectroradiometer measured the specific wavelength bands of ultraviolet and visible wavelengths to ensure compliance to the client’s spectral requirements.

Final testing of the output optical characteristics fulfilled all required criteria from the client. The system was able to achieve an almost perfect spectral match to the required spectral profile over the 280nm-700nm region.

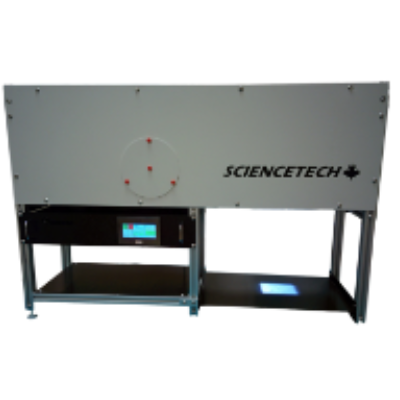

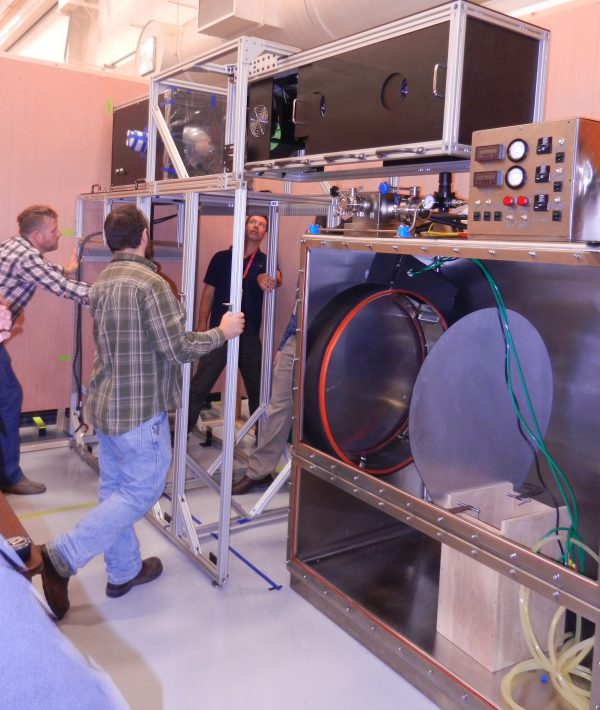

Sciencetech engineers assembling and testing the final solar simulator system

The client traveled to Sciencetech for on-site acceptance testing and signing off that all the requirements were met. The system was carefully packaged into a crate and shipped to the client’s facility, after which the Sciencetech engineering team reassembled, installed, and tested the system. A subsequent visit by Sciencetech’s engineering team was requested by the client to help with moving the system from where preliminary studies were performed to the final installation location.